For professional cross-border sourcing agents, maintaining consistent product quality is one of the biggest operational challenges. The Pingubuy Spreadsheet emerges as a central tool for standardizing the entire quality control (QC) process, enabling agents to establish and enforce uniform inspection standards that build reliability and client trust.

Creating Standardized QC Checklists by Category

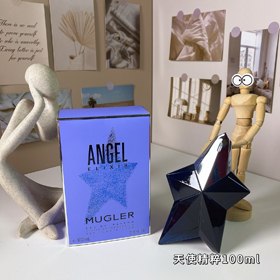

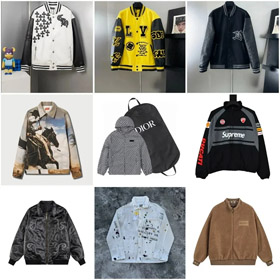

The core function of the Pingubuy Spreadsheet is to allow agents to develop detailed QC template checklists tailored to specific product categories. This ensures every item is inspected against the same critical criteria. For example, templates dictate checking sizing, fabric composition, and stitching for apparel; examining packaging, expiration dates, and seal integrity for cosmetics; and assessing material, hardware, and load-bearing capacity for bags. High-value items like watches require their own specific checklist, focusing on movement accuracy, case and bracelet condition, crystal clarity, and the functionality of complications and crowns. Standardizing these checklists removes subjectivity and ensures nothing is overlooked.

Implementing a Clear Scoring & Disposition System

Beyond simple checklists, the spreadsheet facilitates a structured scoring system. Each item can be rated as Excellent, Acceptable, or Unacceptable based on the inspection. Crucially, the tool logs the disposition for non-conforming items—whether it was returned to the supplier, exchanged, or sold at a discounted price with full disclosure. This creates an auditable trail for inventory management and financial reconciliation, turning QC data into actionable business decisions.

Analyzing Supplier Performance & Optimizing Partnerships

Perhaps the most powerful, long-term benefit is supplier performance analytics. By tagging inspected items with their supplier source in the Pingubuy Spreadsheet, agents can automatically calculate QC pass rates for each vendor. This data reveals which suppliers provide consistently high-quality watches, apparel, or electronics, and which are a source of constant defects. Sourcing agents can then strategically adjust their procurement strategy, directing more business to reliable partners and either retraining or phasing out underperformers. This data-driven approach proactively elevates overall supply chain quality.

Building Client Trust and Minimizing Disputes

A standardized QC process, documented within the Pingubuy Spreadsheet, directly translates to enhanced customer confidence. Agents can provide clients with consistent quality assurances, knowing every item meets a verified standard. This drastically reduces the rate of post-sale disputes, returns, and negative feedback related to product condition. For clients, knowing their agent uses a rigorous, transparent system for inspecting everything from luxury watches to everyday goods makes the service inherently more trustworthy and professional.

In summary, the Pingubuy Spreadsheet transforms ad-hoc quality checking into a scalable, analytical, and professional operational pillar for cross-border sourcing businesses.