In the fast-paced world of cross-border shopping and purchasing agency services, maintaining consistent product quality is paramount. Professional agents have discovered that a Pandabuy spreadsheet, when combined with meticulous Pandabuy QC (Quality Control) procedures, serves as an indispensable toolkit for managing supplier quality and preempting customer service issues. This systematic approach goes beyond simple order tracking, transforming into a central hub for quality assurance.

Streamlining Inspection Records

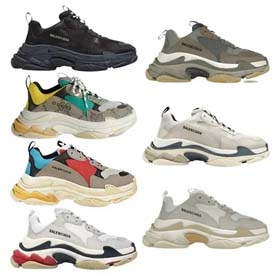

The core function involves creating a dedicated QC log within the spreadsheet. For every batch of items sourced—from electronics and apparel to popular categories like Bags and Bags from various designers—agents document the comprehensive results of their Pandabuy QC check. This includes a detailed assessment of whether the items meet specifications for appearance, precise dimensions, and full functionality. It is crucial to note any defects, damage, or instances of incorrect/missing items. Furthermore, agents can embed direct links to cloud-stored QC photos or add clear notes on their file location, creating an easily accessible visual audit trail for future reference.

Enhancing Customer Communication and Trust

When a client inquires about the condition of their purchased goods, the agent no longer needs to sift through disjointed messages or photos. A quick search within the organized Pandabuy spreadsheet retrieves the exact QC record for that item or batch, allowing for immediate, transparent, and factual feedback. This capability significantly reduces response time and builds immense client confidence, demonstrating a professional and organized operation committed to quality.

Driving Data-Driven Sourcing Decisions

Beyond record-keeping, the true power of this system lies in analytics. Agents can leverage their spreadsheet to calculate QC pass rates across different product categories. This data reveals critical patterns: perhaps certain suppliers of leather Bags consistently have sizing variations, or cosmetics shipments are prone to packaging damage during transit. With these insights, agents can proactively adjust their strategies. This may involve shifting procurement to suppliers with higher QC合格率, or adding clear disclaimers about common, minor imperfections (like non-functional stitches in handmade items) in product listings. Such informed actions minimize future disputes and set accurate customer expectations.

Conclusion

Ultimately, implementing a standardized Pandabuy QC process within a master Pandabuy spreadsheet is a best practice for serious shopping agents. It transforms quality control from a reactive task into a proactive, strategic business function. By ensuring every item—especially high-ticket goods like designer Bags—is thoroughly vetted and documented, agents safeguard their reputation, optimize their supplier relationships, and foster lasting trust with their international clientele.