For independent cross-border purchase agents, maintaining consistent quality control (QC) across diverse product categories is an ongoing operational challenge. Without standardized procedures, inconsistencies in inspection can lead to dissatisfied customers and costly disputes. The Kakobuy spreadsheet has emerged as a core organizational tool that enables agents to establish, implement, and monitor a unified QC protocol, transforming ad-hoc checking into a professional, reliable process.

At the heart of this system is the ability to create detailed QC standard templates tailored to specific product types. These templates define the precise inspection points for each category, ensuring every item is evaluated against the same criteria. For instance, clothing inspections focus on size accuracy, fabric quality, and stitch integrity. Cosmetic items require checks for original packaging, expiration dates, and seal integrity. For bags and luggage, agents assess material authenticity, hardware function, and load-bearing capacity.

Implementing a Structured QC Scoring System

The spreadsheet moves beyond simple checklists by incorporating a formalized QC scoring system. Each inspected item receives a clear grade – Excellent, Pass, or Fail – based on objective criteria defined in the template. More importantly, the tool forces clarity on actions for non-conforming items. When a product fails inspection, the agent immediately logs the next step: return to supplier, request a replacement, or approve the item for sale at a discounted price with transparent disclosure to the end buyer. This documented decision trail is crucial for accountability and process improvement.

Strategic Insights and Supplier Performance Tracking

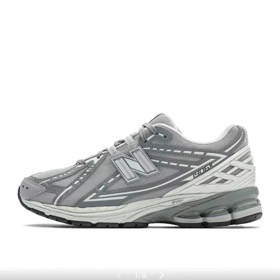

One of the most powerful, data-driven applications of the Kakobuy spreadsheet is supplier performance analytics. By logging QC results over time, purchase agents can generate clear statistics on each supplier's product qualification rate. This data reveals which partners consistently deliver items meeting the defined 'Pass' or 'Excellent' standards, and which ones introduce quality risks. Agents can then strategically adjust their procurement partnerships, allocating more business to reliable suppliers and either working with or discontinuing relationships with underperforming ones. For example, tracking shoes and sneakers QC data might reveal one supplier excels in athletic footwear authenticity but another has issues with inconsistent sizing in dress shoes. This granular insight informs smarter buying decisions.

Building Customer Trust Through Visible Standards

The ultimate benefit of this standardized QC workflow is a significant reduction in post-sale disputes and a corresponding increase in client trust. When customers know their purchase agent follows a rigorous, documented inspection process – especially for high-value categories like designer handbags or premium sneakers – their confidence in the service grows. The agent can even share selective aspects of their QC checklist as a selling point. In a market where trust is the primary currency, a professionalized approach to quality assurance sets serious purchase agents apart from casual resellers.

In summary, the Kakobuy spreadsheet transcends its basic function as a digital ledger. It serves as the foundational tool for cross-border purchase agents to systematize quality inspections, make data-backed supplier decisions, and professionally manage product exceptions. This operational discipline not only minimizes losses from defective goods but also builds a reputation for reliability that is essential for long-term business growth in the competitive world of cross-border resale.